A VolksCruising, Blue Water TriloBoat

By Dave Zeiger at triloboats.blogspot.com

Full disclosure… Anke and my blue water experience is entirely vicarious. I do not recommend a TriloBoat to venture far offshore as I lack blue-water performance data.

I can confidently say a TriloBoat hull wouldn’t be the worst choice. A good design, built robustly and competently handled, they should survive anything a similar vessel can, and do so more comfortably than many.

In a VolksCruiser, I look for:

- Tolerably small (small is beautiful! – E.F.Schumacher)

- Simple hull shape (easily lofted, easily built)

- Simple construction (straightforward build from common materials)

- Simple interior (avoid complicated spaces, joinery or detail)

- Simple, durable finish (wipe-down, if possible; avoid varnish)

- Simple, basic systems (avoid unnecessary, complex, unrepairable)

- Simple, robust gear (good quality, fix-it-yourself)

- Simple, robust rig (low stress, fail-safer)

It is the combined economies of these points that keep overall costs down, and often make the difference between Go Now and Go Never.

Our personal approaches add:

- Flat bottom (easiest build, greatest volume/displacement on given dimensions)

- Square sections (easiest build, highest form stability / volume / displacement, reduces ballast)

- Ultra shoal draft (offers a hundred harbors to every deep one)

- Outboard rudder (external, inexpensive, easy maintenance)

- Retractable Lateral Resistance (lee-, center-, dagger or off-center boards (our fave)

- Free standing, junk rig (inexpensive, simple to use, maintainable with DIY materials, fail-safer)

- Copper plating (long lasting, non-toxic anti-fouling, mechanical protection… works particularly well with flat bottoms and panel designs)

And last, but not least:

- Move aboard (If you don’t, let’s face it; our vessel is an expensive toy)

WAYWARD

Our current TriloBoat, WAYWARD at 32 x 8 x 1-1.5 feet, represents our state-of-the-art nearshore VolksCruiser thinking for two. We sail and scull engine-free in Southeast Alaska.

Her layout… large cutouts in interior bulkheads… total cabin space is 20ft x 8ft… ample for two:

Adjacency is arranged for the following reasons…

- Bunk – Salon: The bunk is at the same height as salon seats, extending the social space. The dinette may be broken down and gangway planked over to form a large, flat interior platform for projects or flexi-space mode with extra storage under.

- Salon – Galley – Cockpit: The galley can service both the salon and cockpit without isolating the cook. Food and beverages can be handed either direction with less risk of spill.

- Galley – Cockpit: In addition, the galley serves as a pilot house. Remote steering is simplified by adjacency. We can sit on the counters with a 360deg view, and access the cockpit directly when necessary. The galley has standing headroom, which allows a wet-locker handy to the companionway. Anke can stand; I sit in the salon.

Her rig is a version of our preferred junk rig. It’s DIY, cheap and easy for a couple to handle blow high, blow low and in the dark o’ night.

Factoring in Blue Water

I believe any vessel that ventures offshore should be prepared to be caught in worst-case weather.

In brief, I accept the sea-keeping proof-of-concepts for shoal draft provided by Monroe’s EGRET and Bolger’s ROMP. They rise over and skitter away from seas rather than shoulder through them and absorb impact. They and others have been proven in hurricane conditions. Wise’s LMII and others do the same for flat-bottomed hulls.

My personal order for storm tactics is to evade, heave-to, run off, set Jordan Series Drogue from stern. I’d prefer the bow, but the US Coast Guard doesn’t recommend it (with bow-deployed drag devices, the hull risks being turned sideways and rolled by breaking seas).

Consequential parameters include…

- Self-righting

- Avoid deep, broach-prone lateral resistance

- Favor retractable lateral resistance (including rudder)

- Encourage downwind tracking (fixed aft skeg)

- Water shedding cockpit

- Poop resistant aft everything (including rudder)

A barge / scow’s generally lighter weight (less acceleration down a wave face) and immenseforward reserve buoyancy (anti-plunging) should, I believe, reduce risk of pitch-poling.

In designing a seagoing Volkscruiser, I would likely work from a TriloBoat toward Yann Quenet’s SKROWL concept, preserving construction simplicity where I could. But, for the sake of discussion, let’s look at minimal changes to the full TriloBoat formula.

To take a TriloBoat offshore I’d include the following design features:

- Heavy bottom and watertight pilot-house (when closed up).

- Roll up the bow to ease plunging contact with green water.

- Aft skeg for aft lateral resistance in aid of downwind tracking.

- Layden chine runners and forward daggerboard for no-trip/broach lateral resistance.

- Full positive buoyancy, with water-tight bulkheads isolating cabin from holds.

- Lower pilot house and rake its leading edge.

- Shutter large windows with track-sliding and bolt-down aluminum plate.

- Hollow, sealed, lightweight masts (that resist roll-over and can be raised and lowered at sea), supported by running shrouds.

- Reinforced mast tabernacles with splayed struts.

- Reinforced holdfasts, fairleads and winch(es) for Jordan Series Drogues.

- Increased ventilation (can’t rely on windows/hatches/doors) with immersion proof designs.

- Water tanks (vs. cannisters) and/or advanced solar still.

- Lee cloths in bunk, port and s’brd, and settee..

- Windvane steering.

- Wafer dinghy stowed flat on the deck crown.

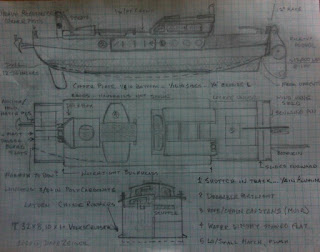

In the following cartoon, I’ve drawn a retractable daggerboard and balanced, kick-up rudder to augment the mid-ships Layden Chine Runners. I’m guessing the daggerboard wouldn’t need to be lowered to max, as shown, in order to be effective.

It needs more thought, over all, but I present this hopeful monster for your consideration…

Thoughts on Construction

Our lower end, ply-foam-ply approach for WAYWARD cost about $10K in 2014 to finish the hull, superstructure and interior (including rent, shipping, tools, etc.). We built remote… savings from scrounging, shopping and transport could reach 25%? Copper plating doubled that to $20K.

At the higher end, glass / foam composites with vacuum bag resin infusion are not as scary as they sound. Materials are initially more expensive, but like copper, prorate well over a long period of time. Maintenance effort and costs drop. I’m guessing it might add another $5K?

If venturing offshore, I would consider a rot-proof hull to be a good investment in on-board insurance. Not like you can pull over for a pit stop.

*****

If Anke and I were to go to sea, I think a vessel with a TriloBoat foundation would be a contender. We can build it with our skills and resources. I believe we’d be at least as safe at sea as most boats of a size.

As the Pardeys sing it… Go Small, Go Simple, Go NOW!

For more thoughts along these lines, the following are a start:

http://abargeinthemaking.blogspot.com/2013/11/baseline-design-against-which-all.html

http://abargeinthemaking.blogspot.com/2013/11/considering-curvier-dogs.html

http://triloboats.blogspot.com/2020/01/fail-safer-hull-design.html

Dave you can easily hand lay some foam panels up on large sheets of glass or shiny MDF. People seem to forget before vacuam infusion if you had a good crew you could still keep those panels fairly light. The other issue with foam/glass is I am not sure how strong it would be compared to solid plywood? Our yacht is 30mm plywood on the bottom and has never given us any issues beaching. But the biggest issue with foam/glass is that it is not a fun material to build with. Give me ply and timber any day.

Cheers

To tell you the truth e're not very gifted builders,and chemicals 'R NOT us. Ply/frame has always been our choice.

That being said, we're around a lot of foam / glass / resin projects (mostly without vacuum bagging) that stand up in Alaskan working vessels. So my impression is that, well done, strength is more than adequate.

One big advantage for us in a wood layer low in the hull is that it simplifies the attachment of copper plate with screws or ring-shank nails.

Really enjoyable post….. been intrigued by the idea of a seagoing trilo awhile. The cartoon looks yummy and packed with creative features (like daggerboard way up front…. cool!). There's a interesting family, of sorts, of bluewater barges posited recently, among them Orlovs Quidnon. Often wondered how a original AS39 would be with no side curvature at all…. kinda along these lines. Also wonder if offshore barge cruisers, built in steel with a 1/2" plate bottom (like Bolgers 45 Weston Martyr sharpie) wouldn't be a mega strong reef cruiser and be self righting. So many boats….. so little time.

That fwd board balanced against the big rudder came to me from Bolgers ST. VALERY. in which it is reported to perform well.

A big advantage – as with cat-ketch rig – is that LR stays outboard of and separated by water-tight bulkheads from cabin spaces.

The Layden chines amidships are used by Chris Morejohn on larger cruising hulls. As I recall, he thought they provided about 1/3 of LR beyond the hull silhouette. I'd have to confirm that, though.